And how to understand what is better? To do this, it would be nice to see the process of producing with your own eyes, make sure that everything is under control that the raw material is only the highest quality.

Recently, a group of journalists and bloggers were invited to see how juices and baby mashed were made. They went to the Lipetsk region and visited the gardens where the apples are grown to produce Frutonian baby food, as well as the progress plant.

Juices contain natural sugars, organic acids, positively affecting the processes of digestion. The first is recommended to prescribe apple juice - it is considered hypoallergenic.

But what apples make this juice? As journalists and bloggers learned, apples for juices and purees "Frutonian" are grown in gardens in the Lipetsk region. This garden has a multi-year story. Apples here are a huge number of varieties, but experts have chosen only those that are suitable for baby food. All raw materials are thoroughly automated control - apples are sorted, in the process of which fruits are selected without defects and damage.

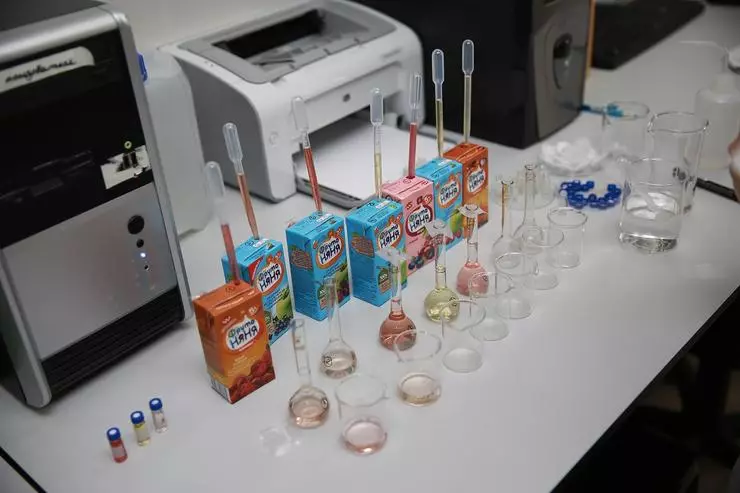

But, of course, a good raw material is just half. What happens to apples on? They go to the plant, where input control in their own laboratory first pass on the presence of foreign chemicals. In the accredited test center, the company is estimated literally everything: taste, smell, physico-chemical and microbiological indicators of apples. In this case, the whole process is automated, the human hand does not apply to anything. If any doubts arise as products, the entire batch is disposed of.

Only after passing the quality examination, apples are sent to the plant. "We pay great attention to the entire process of the production of juice: from the development of a formulation to the release of the ready-made product party," says Dmitry Makarkin, Director of Innovation and Management of Progress JSC. - "We actively cooperate with the Scientific Center for the Health of Children and Food Rams, attract their experts for independent verification and evaluation of our products, carry out regular joint research."

Next, selected apples pass five degrees of cleaning. Fruits are spoiled several times, sorted. Then the fruits fall into the apparatus for pressing the juice with the pulp, which allows you to preserve all the nutrients of the fruit, including food fibers. In the process of grinding, peel and grain are separated. Squeezed juice is heated for a short time (this is not reflected in the number of vitamins, but allows you to protect the rapid body of the baby). The next stage is clarification - the juice becomes transparent and without impurities. And then goes to the conveyor on the spill in the package. The entire technological cycle is fully automated and equipped with modern high-tech equipment. It is important to note that sugar, taste amplifiers and other non-healthy substances are not added in the puree and juices.

At the Progress Plant in Lipetsk, there is also a production of direct spinning with several components: an apple-pear. All ingredients are added automatically using a special counter, according to the recipe.

Each batch of juice is complementary control in the laboratory - the heart of the plant. And after the juices bloom in the packaging and fusing in the boxes.

Parents can be completely calm - juices and purees "Frutonian" will bring their children only benefit.

Arina Petrov

Photo: Progress JSC